Doweled drawer corners refer to a construction technique used to join the corners of drawer boxes in furniture. This method involves the use of dowels, which are cylindrical wooden rods or pins, to strengthen the joints where the sides of the drawer meet the front and back panels. Here’s a detailed look at doweled drawer corners:

1. Construction Method

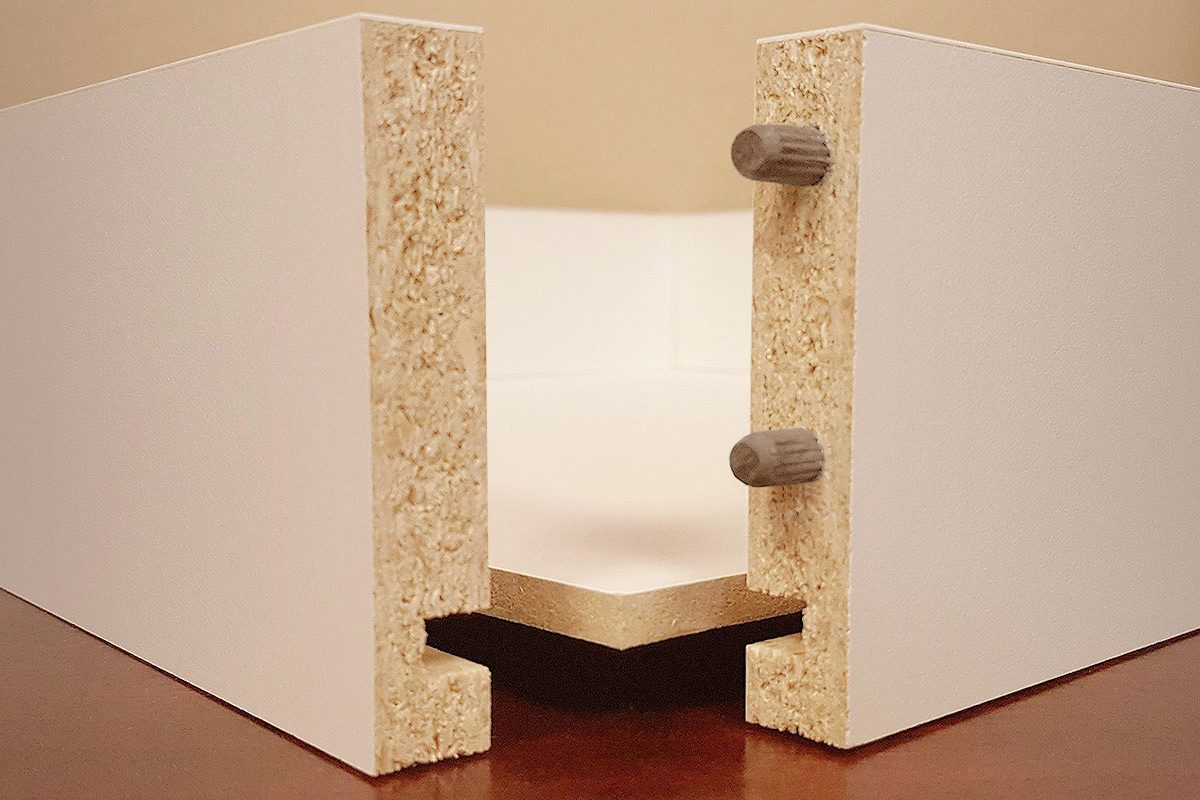

- Dowel Placement: Dowels are inserted into pre-drilled holes in the corners of the drawer. Typically, one dowel is placed in each corner joint.

- Joining Parts: The dowels align and connect the drawer sides to the front and back panels, holding them together securely.

- Adhesive: Wood glue is often used along with dowels to reinforce the joint and provide additional strength.

2. Advantages of Doweled Drawer Corners

- Strength and Stability: Dowel joints enhance the structural integrity of the drawer by providing a strong, precise connection between the components.

- Accuracy: Dowels help in aligning the pieces accurately, resulting in well-formed corners and a sturdier drawer.

- Aesthetics: Dowel joints are typically less visible than other joint types, which can result in a cleaner appearance, especially if the drawer is painted or finished.

3. Types of Dowel Joints

- Straight Dowels: Simple cylindrical dowels inserted into matching holes in the adjoining pieces.

- Pocket Dowels: Dowels are inserted into pocket holes drilled at an angle, providing additional stability.

4. Comparison to Other Joint Types

- Compared to Screws: Doweled joints often provide a stronger and more stable connection without the need for visible hardware.

- Compared to Dovetail Joints: Dovetail joints are also strong and traditional, but doweled joints can be simpler and more cost-effective to produce.

5. Applications

- Drawers: Commonly used in drawer construction for both residential and commercial furniture.

- Cabinets: Can also be used in cabinet construction where precise, strong joints are required.

6. Installation Process

- Drilling: Holes are drilled into the edges of the drawer components where they will join.

- Inserting Dowels: Dowels are inserted into the holes, aligning the components.

- Applying Adhesive: Wood glue is applied to the dowels and the connecting surfaces for a strong bond.

- Assembling: The drawer components are brought together and clamped until the adhesive dries.

What Are Dowels Made Of?

Dowels can be made from metal, plastic, or more commonly wood. In custom drawer and cabinetry the internal dowel joints are made of wood. For cabinet shelves metal dowels are very common. They are good choices for the moving of shelves. This is good for moving shelves but wooden dowels are used for custom drawer manufacturing as they have increased grain and friction inside the drilled holes and increased durability.

Custom Dowel Joint Drawer Production

Drawer Connection, Inc. has been making customer drawers since 1997 and can produce any drawers you need. Be it dovetail or dowel we can custom make the drawers you want for your kitchen, custom closet organization system, bathroom cabinetry or anywhere else you need to have drawers. Give us a call to get your project started at 1-877-917-4887. Stay tuned for more from the expert drawer box manufacturers at DCDrawers.com