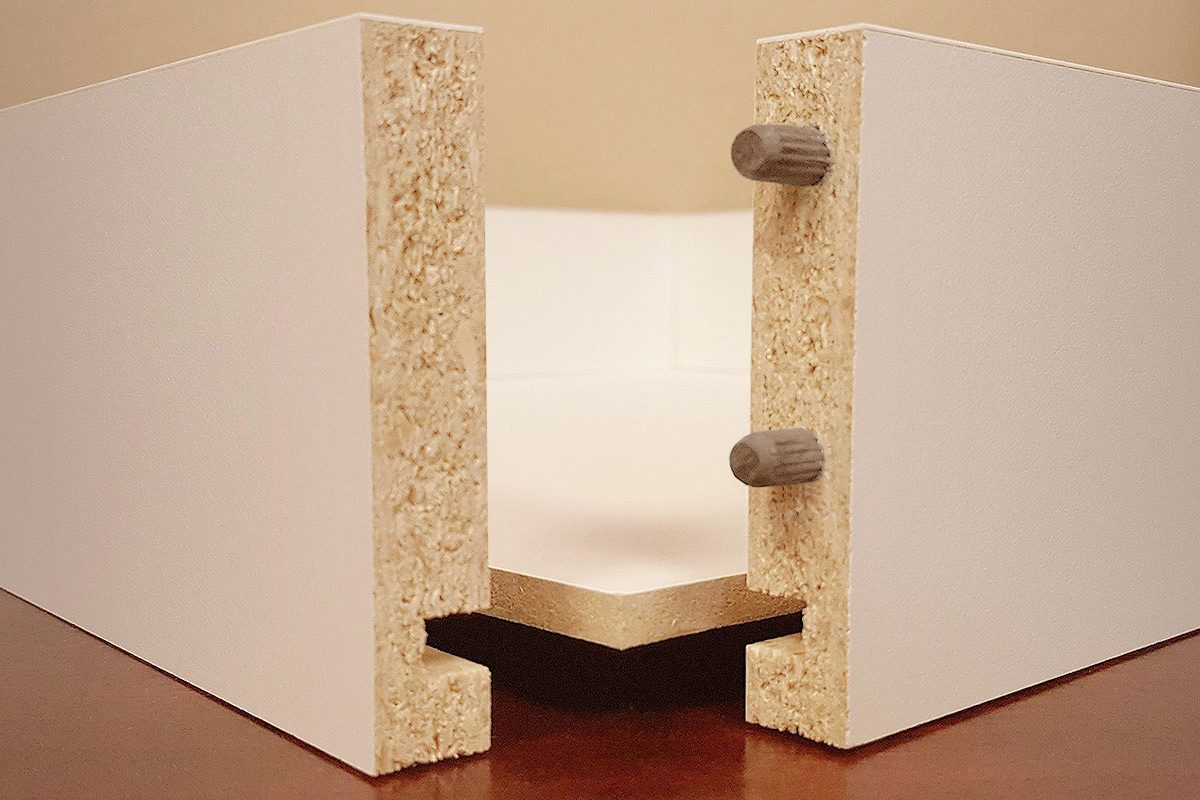

Dowels joints are a way that drawers sections are fastened together. Including dowels in the connecting sections of wood make more accurate, stronger connections that simply using glue alone. Dowel joints are incredibly strong and visually attractive if they are done right. This type of joint is very popular for drawers or other woodworking in which a butt joint is being used. It helps increase the strength and durability of the joint.

What Are Dowel Joints Used For?

Dowel joints are used in a wide variety of woodworking projects. They offer a number of benefits during production and after.

Increased Strength – Miter and butt joints are sometimes only glued together. This means that the stresses of whatever use the wood sees will wear on the joint. Humidity can also dry out or cause glue to lose its adhesive properties. Dowels are added to the joints by drilling into each joining piece of wood so the corresponding holes share a dowel. Having the dowels physically connect the wood dramatically increases strength.

Keeping It Straight – When producing wood products without dowels it can be a challenge to glue and clamp down the pieces without them moving during the drying and setting time. The inclusion of dowels ensures that everything is perfectly lined up and when glued and clamped it is perfectly straight and dries stronger.

Pin Joints – Certain types of joints require the ability to twist. Dowels are generally round in shape, which allows a certain level of twisting. This is easier and more simple than other tail-and-pin joints.

Dowels Work Better Than Biscuits – Biscuit cuts are easier and faster to make but are not as strong or durable. The material is thin and has a possibility to absorb humidity and swell. This can mean a bulge in the joint material and the extra stress can cause it to loosen or fail entirely.

Advantages Of Dowel Joints

No Need For Metal Fasteners – Nails, staples, and screws are fine when found behind sheetrock. For custom drawers or other fine interior cabinetry features they are visually disturbing and upset the grain patterns we all love. Dowels do the job while not being seen.

Increased Durability And Strength – Because the wooden dowel runs inside the connecting wood sections it holds fast and is much stronger. Nails, screws or staples are thinner and many times are not properly installed. They can stretch and splinter the wood making it weaker. This adversely affects the lifespan of whatever wooden structure is being made.

What Are Dowels Made Of?

Dowels can be made from metal, plastic, or more commonly wood. In custom drawer and cabinetry the internal dowel joints are made of wood. For cabinet shelves metal dowels are very common. They are good choices for the moving of shelves. This is good for moving shelves but wooden dowels are used for custom drawer manufacturing as they have increased grain and friction inside the drilled holes and increased durability.

Custom Dowel Joint Drawer Production

Drawer Connection, Inc. has been making customer drawers since 1997 and can produce any drawers you need. Be it dovetail or dowel we can custom make the drawers you want for your kitchen, custom closet organization system, bathroom cabinetry or anywhere else you need to have drawers. Give us a call to get your project started at 1-877-917-4887. Stay tuned for more from the expert drawer box manufacturers at DCDrawers.com